Heat Exchanger Design Method

The Hybrid Method applied to plate finned tube evaporators

The modeling of tube and fin heat exchangers working as evaporators is hard for the presence of a two-phase flow, a heat transfer process of moist air stream, condensate mass transfer and complex geometries. Therefore, traditional rating methods can be unable to adequately predict their performance.

The modeling of tube and fin heat exchangers working as evaporators is hard for the presence of a two-phase flow, a heat transfer process of moist air stream, condensate mass transfer and complex geometries. Therefore, traditional rating methods can be unable to adequately predict their performance.

The modeling of tube and fin heat exchangers working as evaporators is hard for the presence of a two-phase flow, a heat transfer process of moist air stream, condensate mass transfer and complex geometries. Therefore, traditional rating methods can be unable to adequately predict their performance.

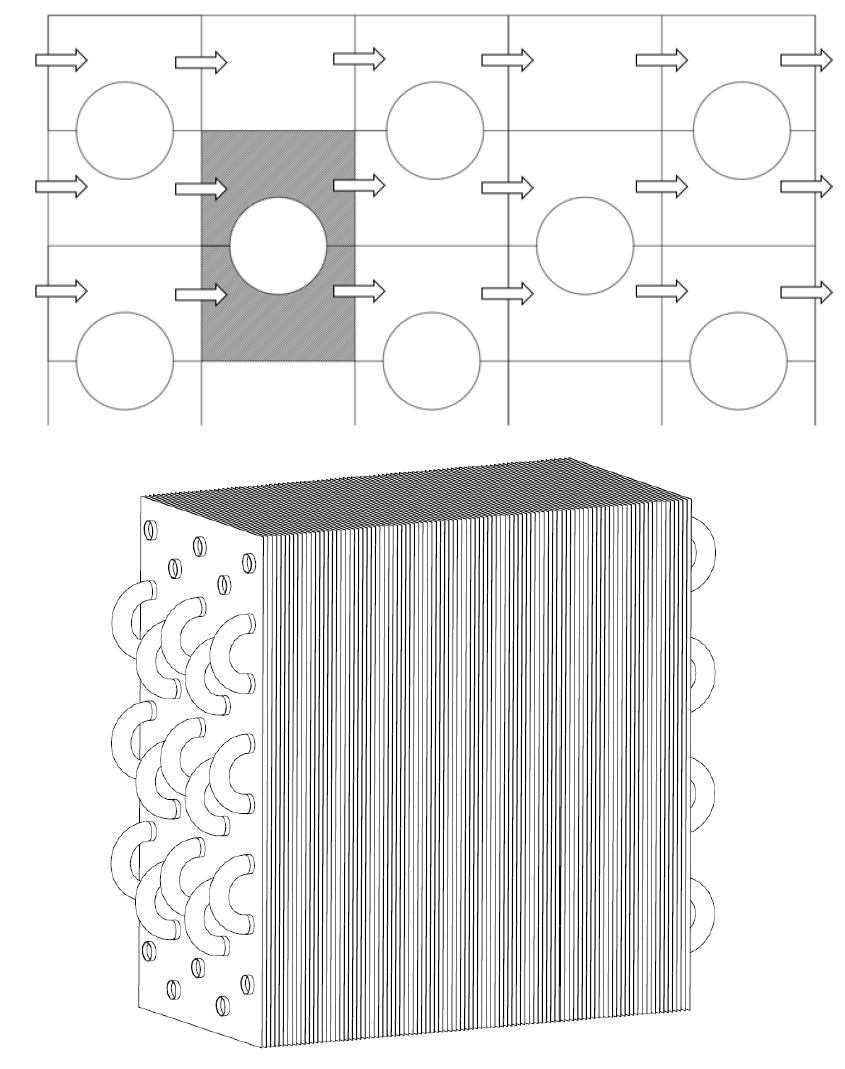

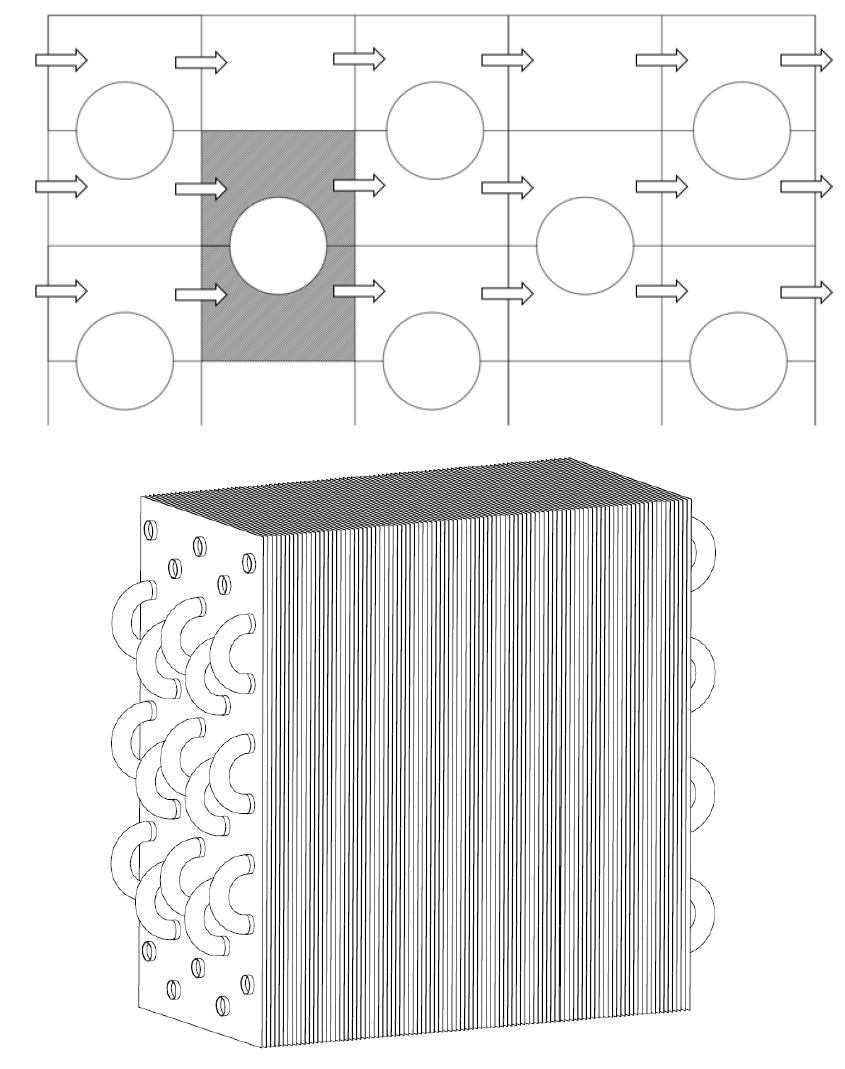

The modeling of tube and fin heat exchangers working as evaporators is hard for the presence of a two-phase flow, a heat transfer process of moist air stream, condensate mass transfer and complex geometries. Therefore, traditional rating methods can be unable to adequately predict their performance. An iterative method, conceived for cross flow compact HXs, was adapted to plate finned tube evaporators introducing a third dimension. Hybrid method uses an analytic and numerical approach to simulate the plate finned tube evaporators performance, starting either from numerical, or analytic or experimental data. The investigated geometry is composed by horizontal, smooth circular tubes, connected by adiabatic return bends and finned with continuous plates. The refrigerant evaporates inside pipes, which are arranged in staggered independent rows. Every coil circuit starts and ends on a single row and all circuits are fed in the same way at the top of the exchanger. The air flows perpendicularly, in the spaces among the fins, so the refrigerant evaporates according to the air inlet conditions on each row.

The plate-fin tube evaporator is divided into a set of control volumes, where at air and refrigerant side, heat transfer takes place and is modeled by means of predictor equations obtained by known data at given conditions. Different cases are analyzed varying the operating conditions for both sides, and the predictor functions for heat transfer performance are obtained with a regression technique.

An iterative analytical method is then used to find at each control volume the convergence between the heat transfer rates on both sides, in order to obtain the actual distribution of wall temperature in the whole heat exchanger and the spatial distribution of the air mass flow rate crossing the heat exchanger.

The plate-fin tube evaporator is divided into a set of control volumes, where at air and refrigerant side, heat transfer takes place and is modeled by means of predictor equations obtained by known data at given conditions. Different cases are analyzed varying the operating conditions for both sides, and the predictor functions for heat transfer performance are obtained with a regression technique.

An iterative analytical method is then used to find at each control volume the convergence between the heat transfer rates on both sides, in order to obtain the actual distribution of wall temperature in the whole heat exchanger and the spatial distribution of the air mass flow rate crossing the heat exchanger.